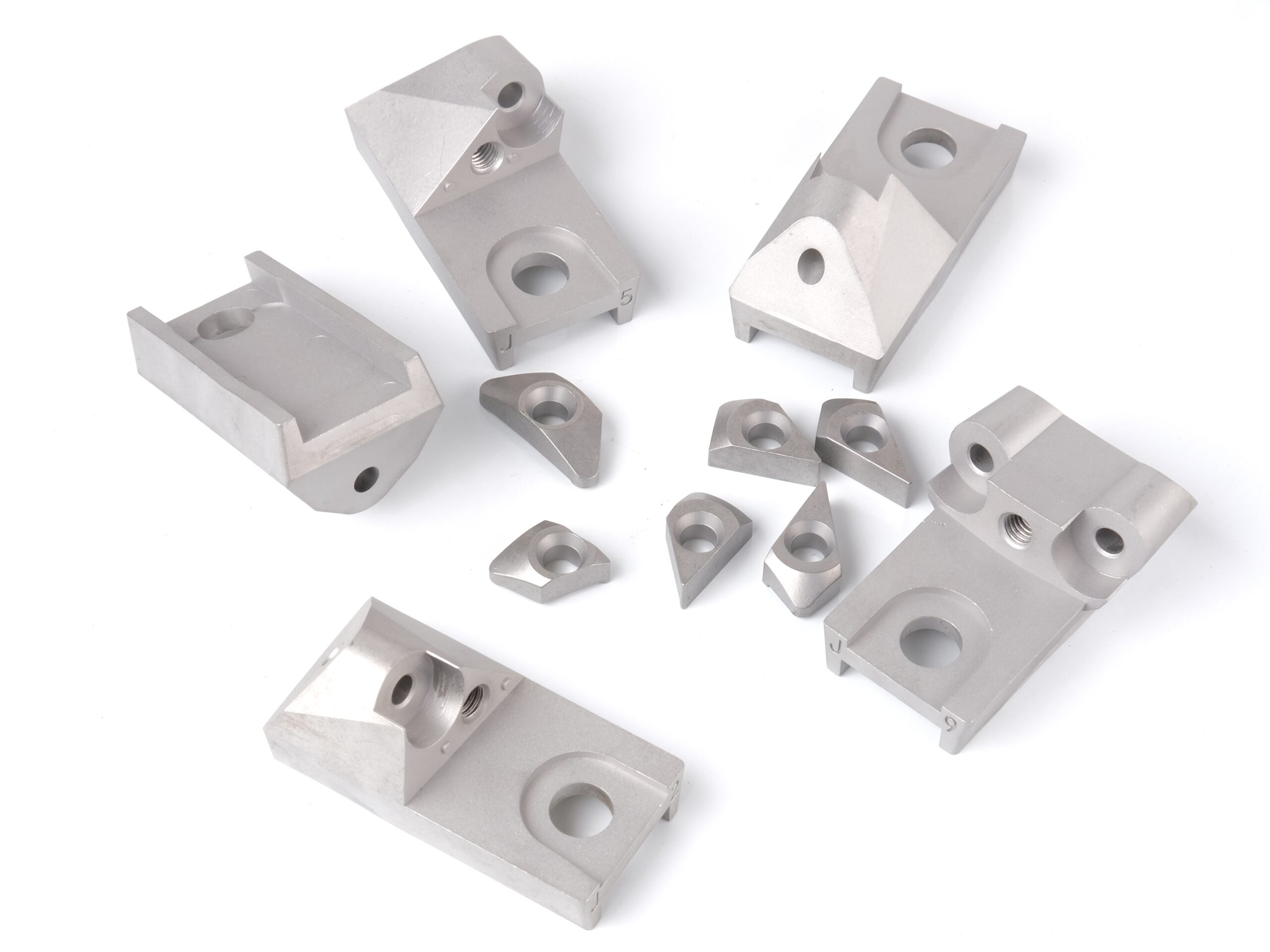

MIM Cutting Holder – AISI 4140

Technical Specifications

Material: AISI 4140

Dimensions: 30 × 28.73 × 60 mm

Weight: 130 g

Surface Finish : Blackened (after heat treatment)

Hardness: ≥ HV450 (heat treated)

Dimensional Tolerance: ±0.5% of nominal dimensions (as per 2D drawing)

Process: MIM (Metal Injection Molding) + Sizing + Heat Treatment + Tapping + Blackening

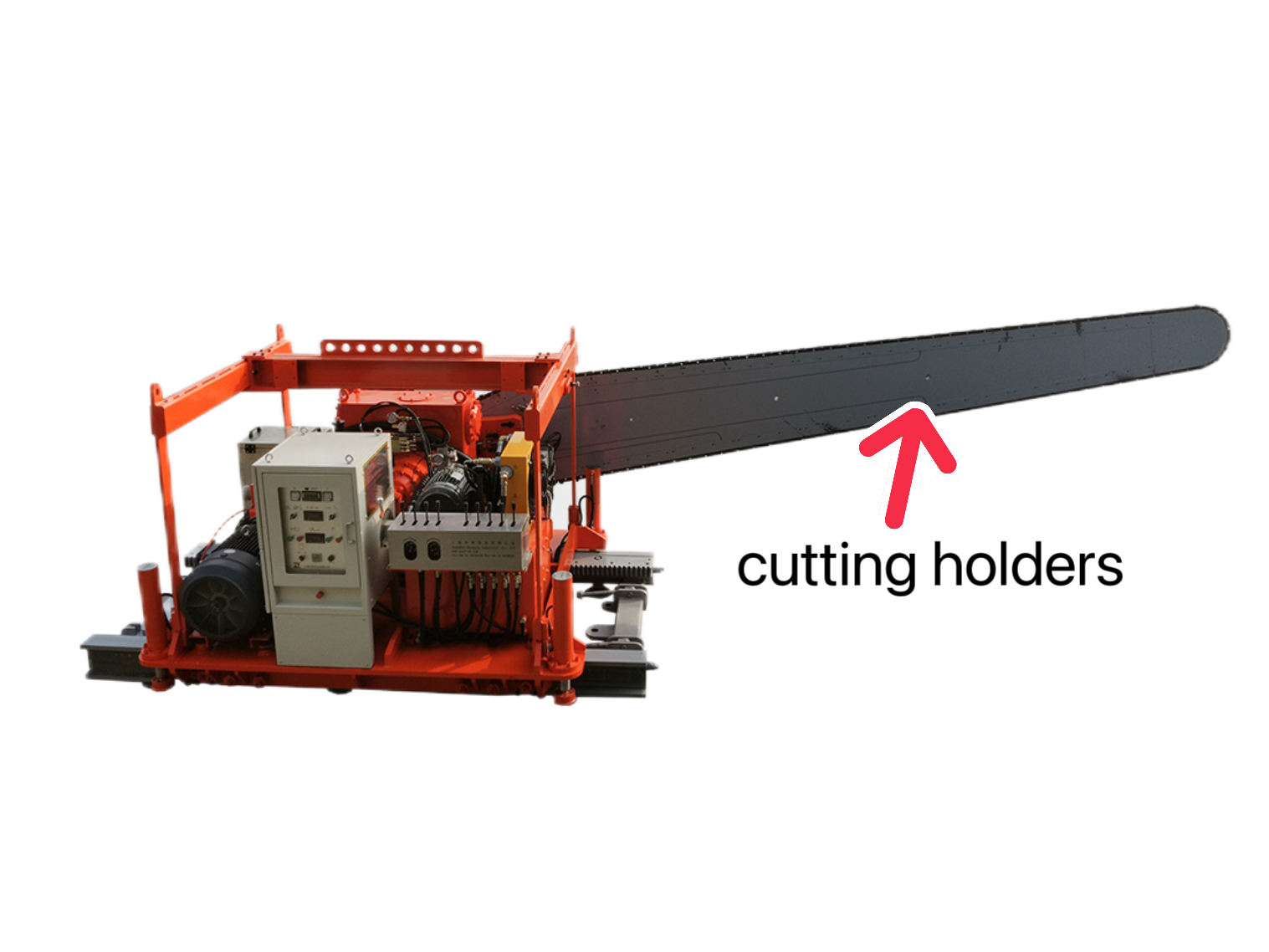

Application: Cutting Holder for Chain Arm Saws / Mining Cutter Bases / Wear-Resistant Mounting Fixtures

This high-strength holder is designed for use in stone and coal chain arm saws. It is manufactured using MIM with post-sinter heat treatment and blackening for enhanced wear resistance, stability, and corrosion protection in harsh working conditions.

Material Properties – AISI 4140

Chemical Composition (%):

C 0.38–0.45 | Cr 0.9–1.2 | Ni ≤ 0.30 | Cu ≤ 0.30 | Mo 0.15–0.25 | Mn 0.50–0.80 | Si 0.17–0.30 | P ≤ 0.035 | S ≤ 0.035 | Fe Balance

Mechanical Properties:

| Property | As Sintered | After Heat Treatment |

| Density | ≥ 7.55 g/cm³ | ≥ 7.6 g/cm³ |

| Yield Strength (RP₀.₂) | ≥ 400 MPa | ≥ 1250 MPa |

| Ultimate Tensile Strength | ≥ 650 MPa | ≥ 1450 MPa |

| Elongation (A₁₀) | ≥ 3% | ≥ 2% |

| Hardness | 130–230 HV | ≥ 450 HV |

Manufacturing Process Overview

The part is molded through metal injection molding and sintered, then precision sized to ensure dimensional stability. It is subsequently heat treated for hardness and fatigue resistance, tapped for insert assembly, and surface blackened to improve corrosion protection during cutting operations.

Injection Molding → Debinding → Sintering → Sizing → Heat Treatment → Tapping → Blackening → Final Inspection

Applications:

- Chain Arm Saw Cutting Holders

- Blade Mounts for Stone and Coal Mining Equipment

- Indexable Insert Holders for Mining Chains

- Shock-Resistant Fixtures for Underground Cutting Systems

Have a similar project in mind?

This part was custom made based on client drawings.

Send us your file and we’ll check manufacturability and offer a quote