Our Capabilities

From Design Review to Quality Control, All Under One Roof

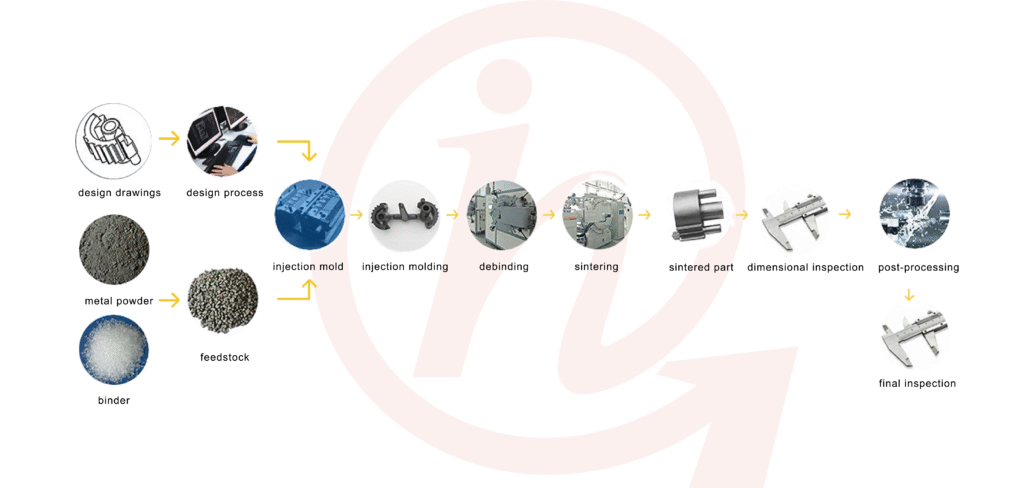

From Concept to Final Part

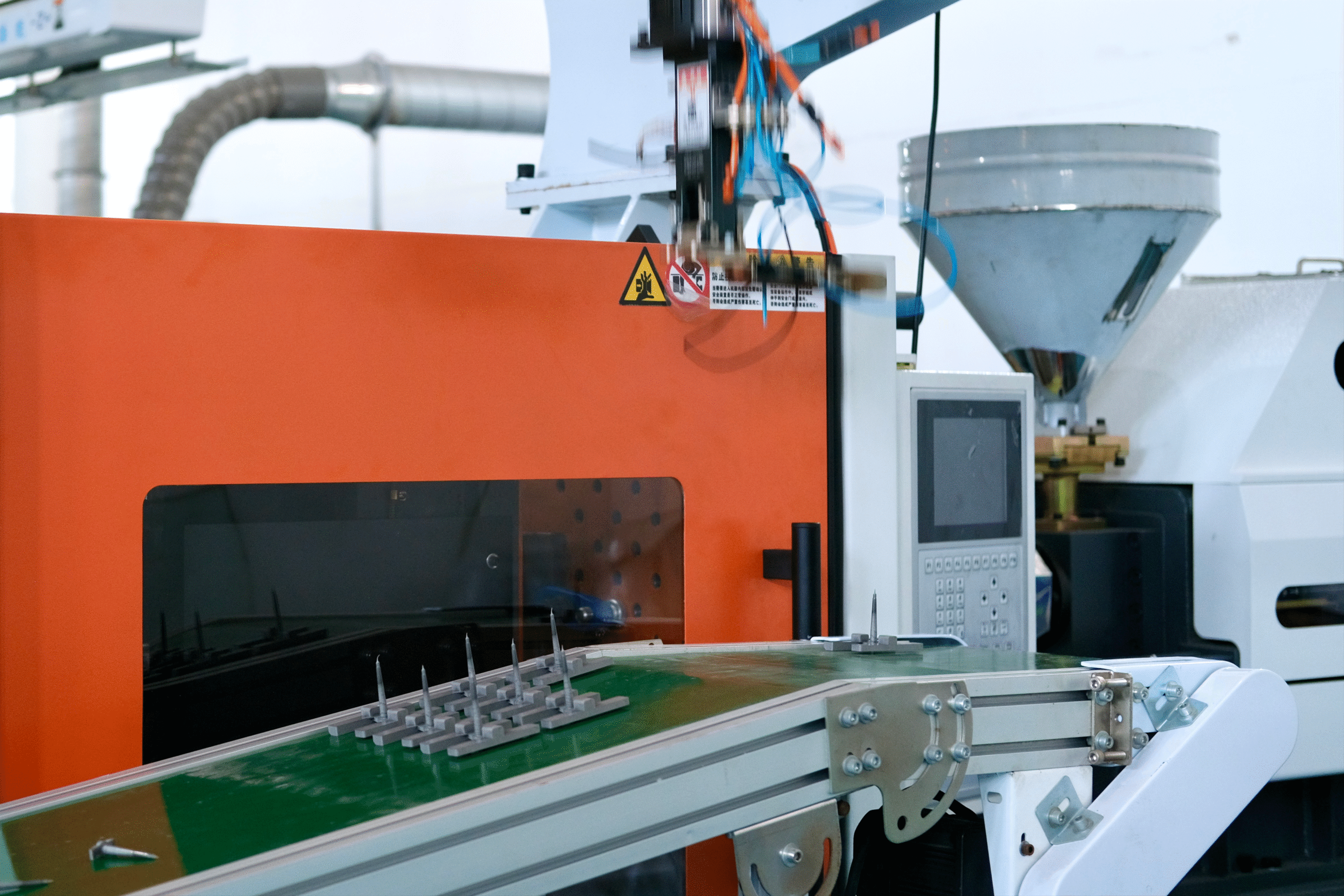

We provide complete metal injection molding solutions, from design review and tooling coordination to injection molding, sintering, finishing, and final inspection. Every step is managed to ensure part quality, dimensional accuracy, and smooth delivery.

Engineering Support for Your MIM Project

We evaluate your drawings to ensure the part is suitable for MIM and optimized for efficient production.

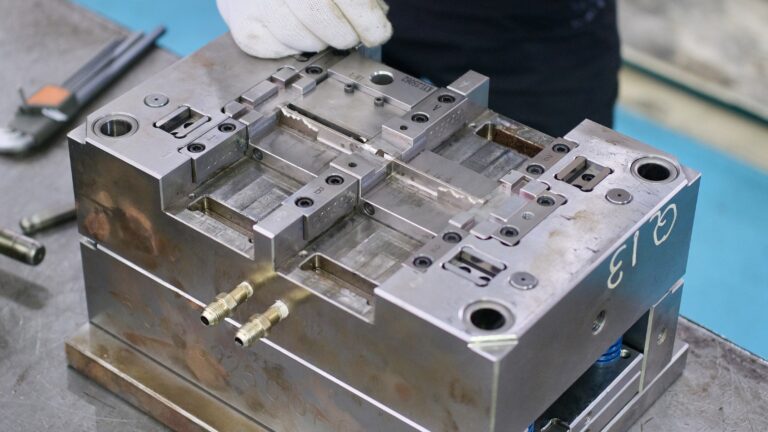

We analyze mold structure feasibility early to prevent tool design risks and shorten lead time.

We identify high-risk areas early to reduce design revisions and improve first-shot success.

Our technical support helps accelerate your timeline from design to stable mass production.

DFM Considerations for MIM Success

Gating

Proper gate location balances mold filling, appearance, and dimensional control.

Sink & Knitlines

Adjusted design minimizes sink marks and improves weld line strength.

Minimum & Maximum Wall Thickness

Keeping consistent wall thickness avoids warping and ensures strength.

Flash & Witness Lines

Strategic design reduces flash and tool parting line visibility.

Ribs & Webs

Structural support features improve stiffness and reduce distortion.

Draft

A slight taper allows easier part ejection and reduces tool wear.

Fillets & Radii

Smooth transitions at corners improve part strength and flowability.

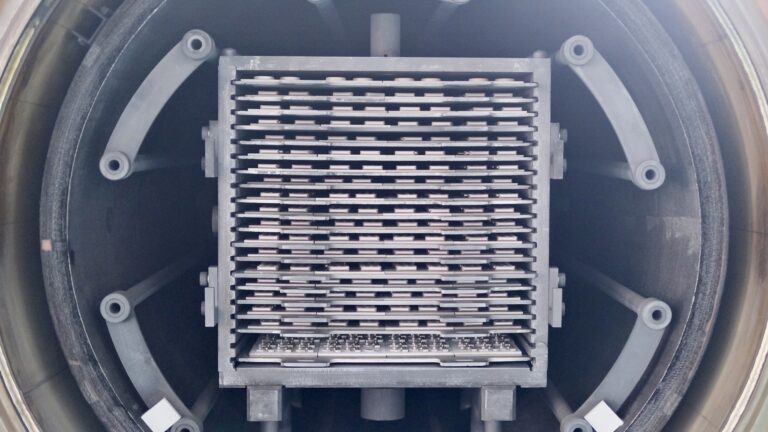

Sintering Supports

Fixtures maintain part shape during sintering and reduce warping.

Dimensional Tolerances

Optimized tolerances balance cost and precision performance.

Interchangeable Mold Inserts

Modular inserts reduce tooling cost for low–mid volume production.

Production Capabilities

Feedstock Mixer

Injection Machines

Dibinding Furnaces

Sintering Furnaces

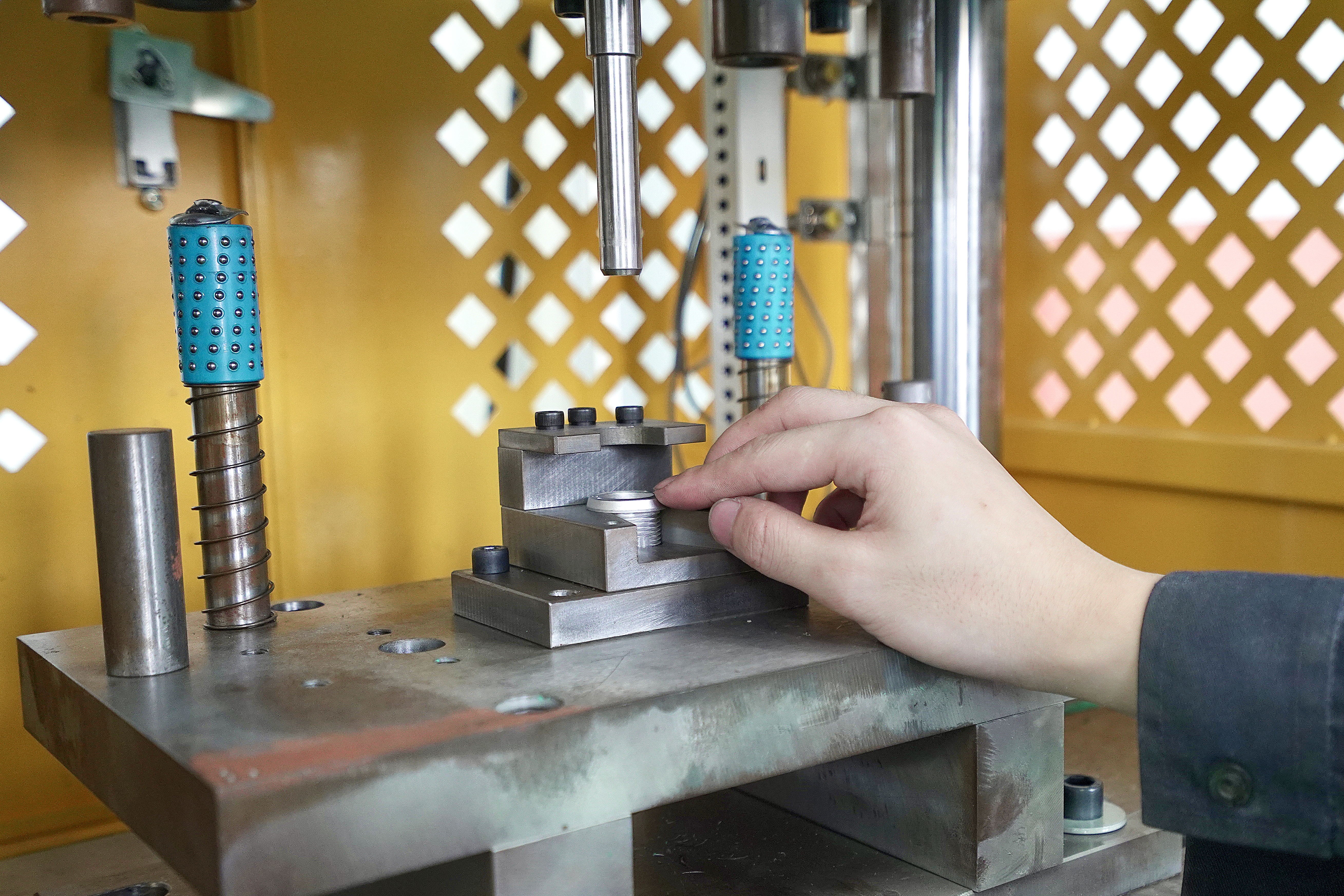

Sizing Machines

Sandblasting Units

Post-Processing Services

Secondary Operations

- CNC

- Tapping

- Chamfering

- Deburring

- Boring / Reaming

- Light Assembly

- Heat Treatment

- Custom Color Identification

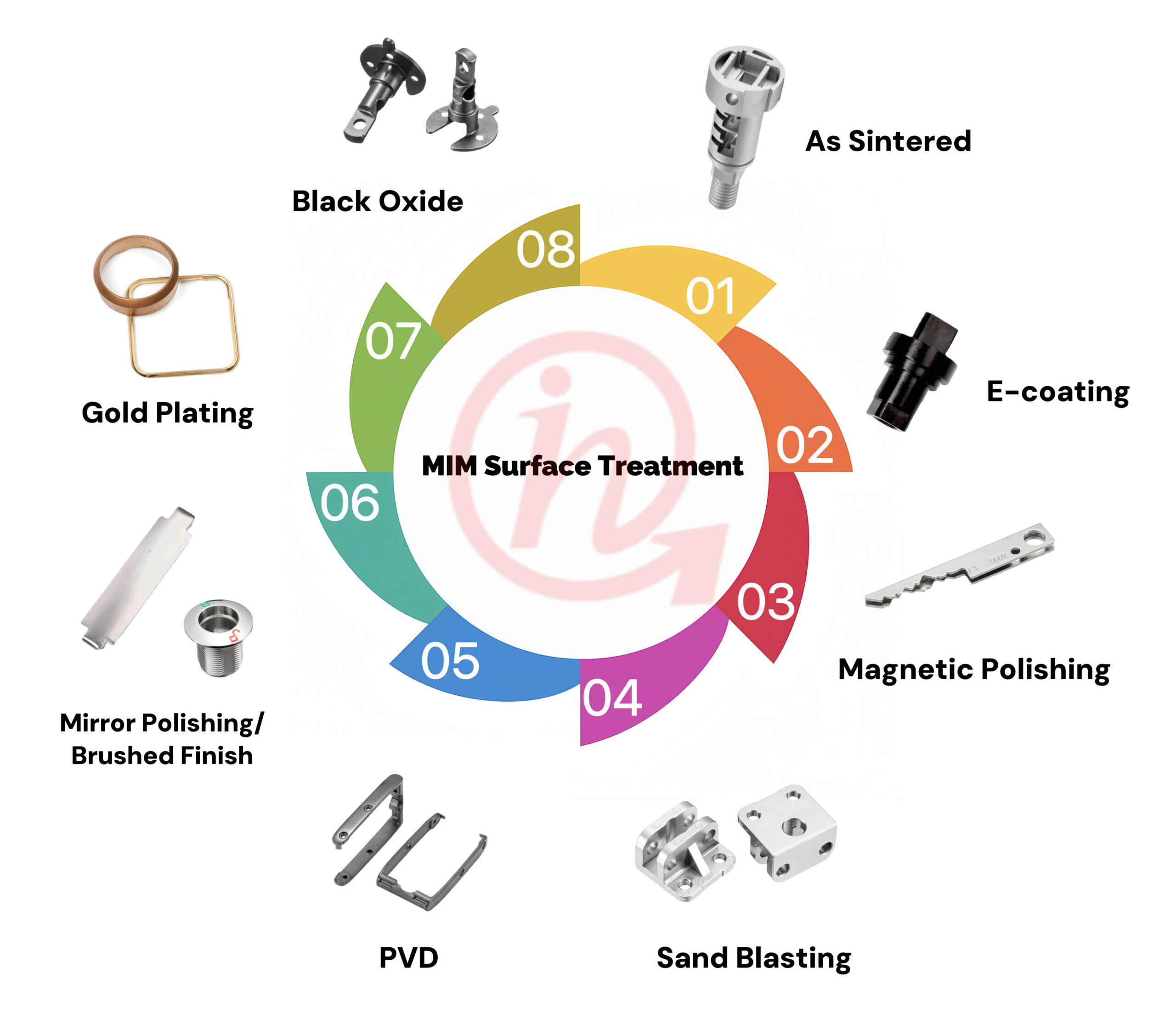

Surface Treatment

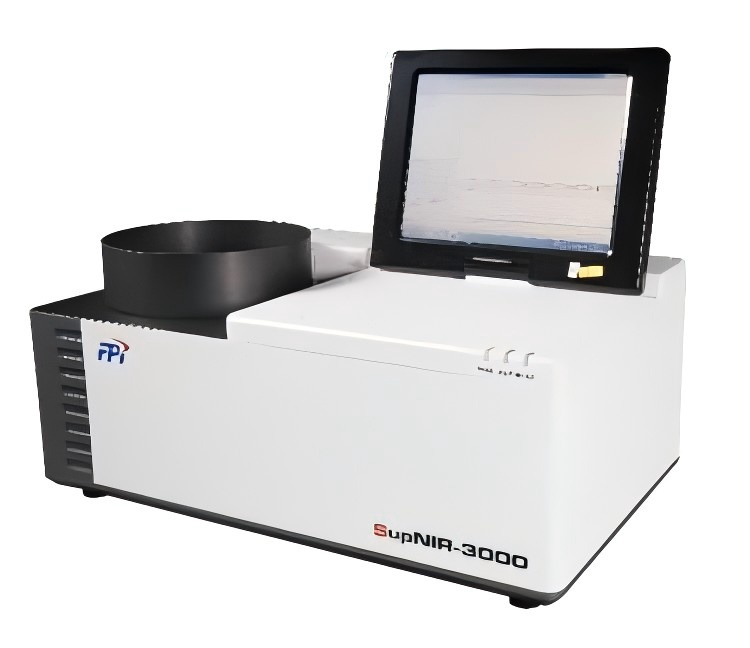

Quality Inspection Equipment

CMM

DENSITY TESTER

HARDNESS TESTER

METALLOGRAPHIC MICROSCOPE

OES

PROFILE PROJECTOR

SALT SPRAY TESTER

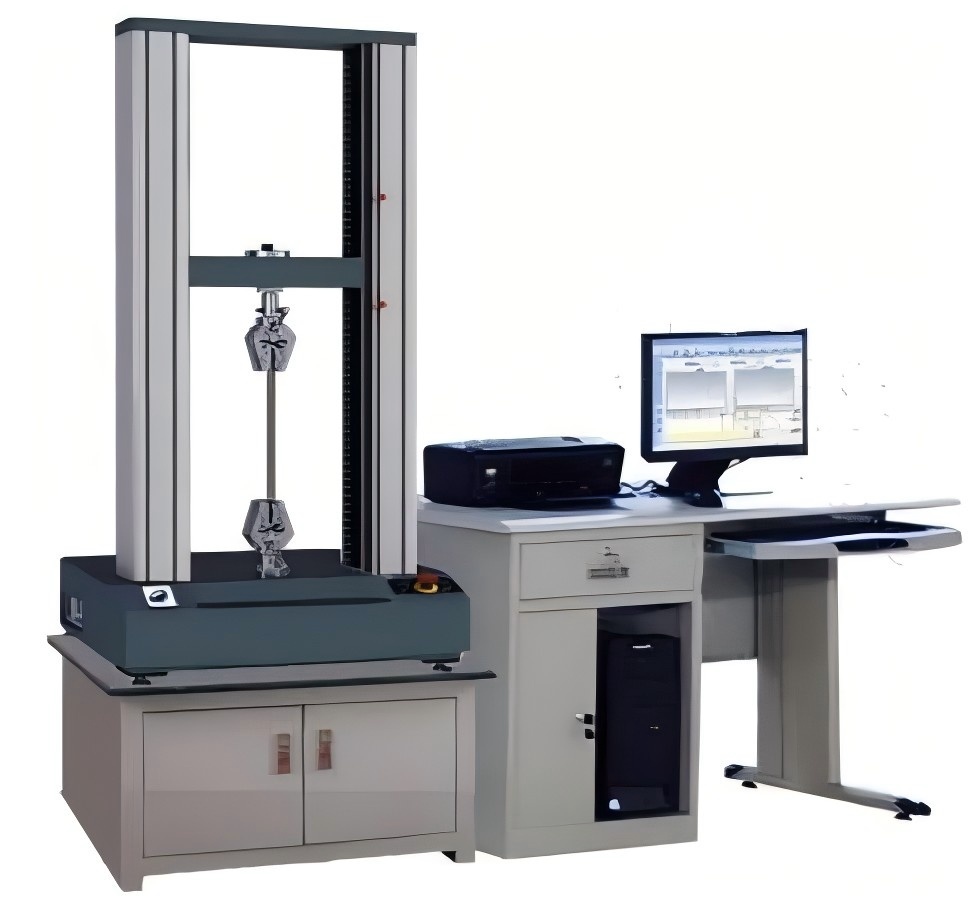

TENSILE STRENGTH TESTER

Need Technical Advice for Your Project?

Discuss manufacturability, material options, or tolerance standards with our MIM engineers.